One of the most pliable synthetic materials available today is Teflon because of its special easy-release and chemical-resistant qualities. It has become an essential component of a variety of industries, including aircraft and cookware.

Although you may think of it as the coating on your skillet, there are many more uses for it. In this blog, you will discover what Teflon is, how it is made, and why it costs so much in different industries.

Teflon is an artificial polymer made from tetrafluoroethylene monomers. Chemically, it belongs to the family of fluoropolymers, represented by powerful carbon-fluorine bonds. These types of bonds give Teflon maximum stability and chemical inertness.

It does not react with most kinds of chemicals and is very stable even under extreme heat or very low temperatures. This unique combination of strength and slipperiness made Teflon widely used across various industries.

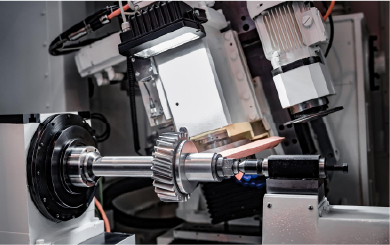

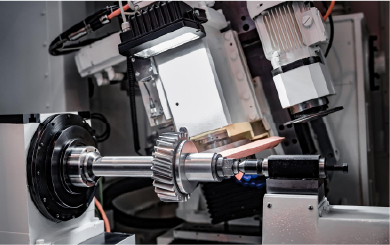

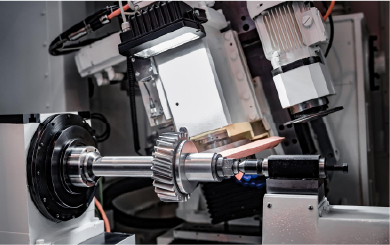

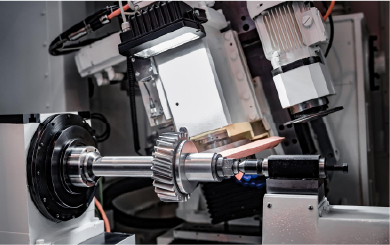

The manufacturing process for Teflon is also known as polymerization. Tetrafluoroethylene gas is converted into solid PTFE resin for high-pressure conditions in a controlled environment. Once produced, the resin is available for compression molding, extrusion, and surface coating.

In cookware, for example, metal surfaces are roughened to improve the adhesion of the Teflon coating. Several layers of PTFE are applied and baked at high temperatures to produce an exceptionally strong, smooth, and extremely durable nonstick surface.

Teflon’s popularity depends on its fusion of unique physical, mechanical, electrical, and chemical properties. The following are tables and insights for each category in depth..

| Property | Value | Description |

|---|---|---|

| Density | 2.1–2.3 g/cm³ | Very Lightweight and Durable |

| Melting Point | 327°C (620°F) | High Temperature Resistance |

| Water Absorption | <0.01% | Extremely low moisture absorption |

| Color | White | Can be modified with fillers |

One of the most pliable synthetic materials available today is Teflon because of its special easy-release and chemical-resistant qualities. It has become an essential component of a variety of industries, including aircraft and cookware.

Although you may think of it as the coating on your skillet, there are many more uses for it. In this blog, you will discover what Teflon is, how it is made, and why it costs so much in different industries.

Teflon is an artificial polymer made from tetrafluoroethylene monomers. Chemically, it belongs to the family of fluoropolymers, represented by powerful carbon-fluorine bonds. These types of bonds give Teflon maximum stability and chemical inertness.

It does not react with most kinds of chemicals and is very stable even under extreme heat or very low temperatures. This unique combination of strength and slipperiness made Teflon widely used across various industries.

The manufacturing process for Teflon is also known as polymerization. Tetrafluoroethylene gas is converted into solid PTFE resin for high-pressure conditions in a controlled environment. Once produced, the resin is available for compression molding, extrusion, and surface coating.

In cookware, for example, metal surfaces are roughened to improve the adhesion of the Teflon coating. Several layers of PTFE are applied and baked at high temperatures to produce an exceptionally strong, smooth, and extremely durable nonstick surface.

Fill out the form below and our team will get back to you promptly with a personalized quote tailored to your needs.